Zhejiang Yongjia County Lin Wanle county magistrate visit ST valve

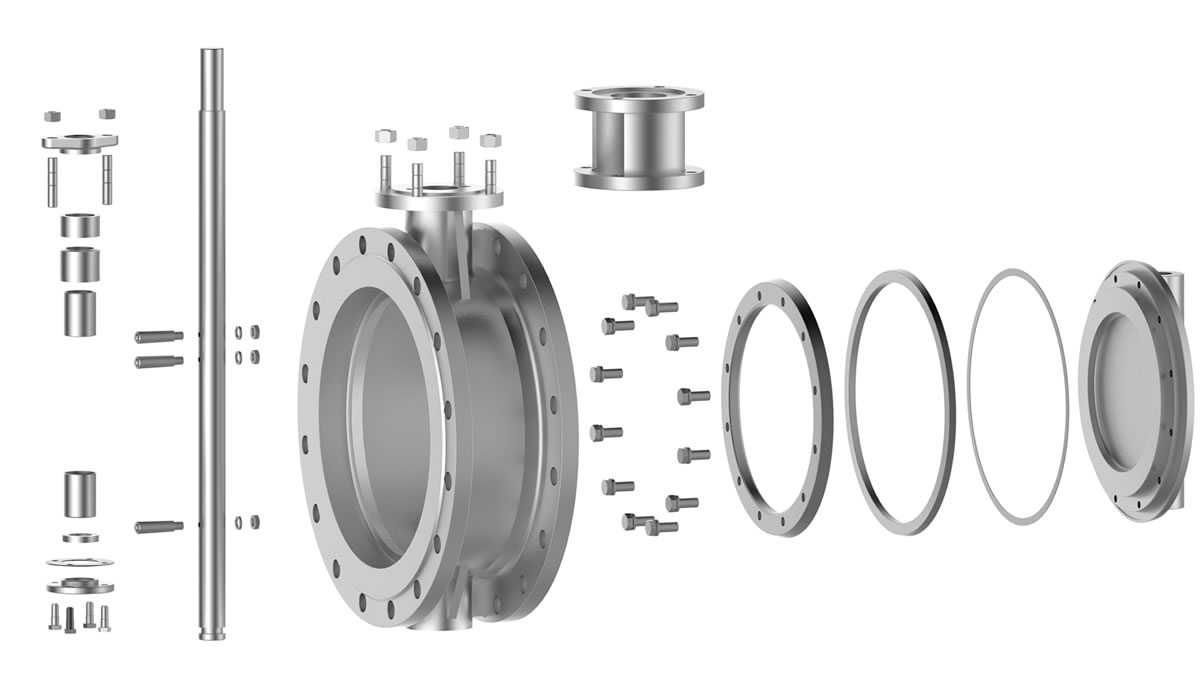

ST triple eccentric butterfly valve USES flange butterfly valve, the stem axis deviates from the disc center and body center at the same time, and the valve seat rotation axis and the valve body channel axis have a certain Angle.In the pharmaceutical, chemical and food industries, flanged butterfly valves are used to interrupt the flow of products (solid, liquid, gas) during production.In many industries, especially in the oil industry, butterfly valves often replace ball valves because of their lower cost.In the system process to transport a variety of corrosive, non-corrosive fluid medium, used to regulate and cut off the flow of the medium.

Handle, worm wheel, electric, pneumatic and other driving devices can be installed according to customer requirements.

Structural Features:

1、ST triple eccentric butterfly valve is designed with double safety structure.There are two independent thrust rings on the upper and lower side of the butterfly plate to ensure normal operation of the valve under any working conditions.

2、In order to prevent stem damage and flying out,independent stem anti-flying structure is designed at the bottom and inside of the valve.

3、Make full use of the sealing principle of triple eccentric butterfly valve,the butterflr plate does not scratch the seat when switching,and the toeque of the valve stem is directly transferred to the sealing surface throngh the butterfly plate,there is no wear point between the butterfly plate and the seat,and the operating toeque is small.

4、The seat is installed directly on the body to reduce the degree of seat erosion and extend the service life of the seat.

5、Thin-layer valve seat structure prevents the sealing surface from occlusions casued by mirco solid and thermal expansion without leakage.

6、Replaceable seal pair.Seats and sealing surfaces are replaceable,reducing maintenance costs.

7、Balanced fixed structure.The sealing pair is fixed by elliptic bolt distribution,and the positioning is accurate,so that the force of each bolt is balanced and the leakage of the sealing pair is eliminated.

8、Fire safety triple eccentric butterfly valve can be produced according to customer requirements,in line with API 607 standard.

9、The packing can be automatically loaded with spring to meet the requirements of mirco leakage.

Design Specification:

Design criteria:API609、GB/T 12238

Structure length:API 609、ASME B16.10、GB/T 12221

Connection standard:ASME B16.5、ASME B16.25、GB/T 9113、HG/T 20592

Inspection and testing:API 598、GB/T 13927、JB/T 9092、GB/T 26480

Fire test:API 607

Pressure and temperature:API 607

Performance parameters:

Main material:carbon steel、stainless steel、alloy steel

Nominal siza:NPS 3"~NPS 80" DN75~DN2000

Pressure range:Class150~1500 PN6~250

Operating temperature:-29℃~+425℃

Application:petroleum、natural gas、chemical、water heating、electric power and other industries